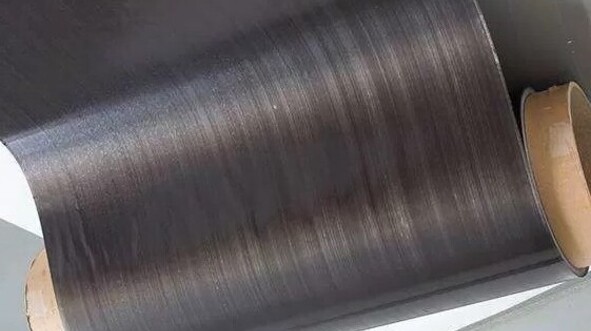

DITF developed tapes from recycled carbon fibers

The increasing use of carbon fiber reinforced plastics (CFRP) in lightweight construction has led to a surge in carbon fiber waste, posing significant environmental challenges. Currently, only 15% of CFRP waste is recycled, with the rest incinerated or landfilled, despite recycling offering greater benefits for climate and resource conservation.

The German Institutes of Textile and Fiber Research Denkendorf (DITF) have developed a novel solution: highly oriented tapes made from recycled carbon fibers (rCF). These tapes, suitable for high-performance applications like automotive structural components, address the limitations of existing recycling methods that reduce CFRP properties.

The innovative process involves combining rCF with thermoplastic matrix fibers, such as polyamide 6, followed by fiber alignment through a modified carding process and subsequent drawing. The result is a continuous, highly oriented tape with mechanical properties comparable to virgin fibers, enabling their reuse in structural applications.

This breakthrough addresses the critical issue of fiber disorientation and shortened lengths during recycling, offering a path toward truly recyclable carbon fiber-based composites. By integrating rCF tapes into production, industries can reduce CFRP waste and its environmental impact while advancing sustainable practices in lightweight construction.

Comment here